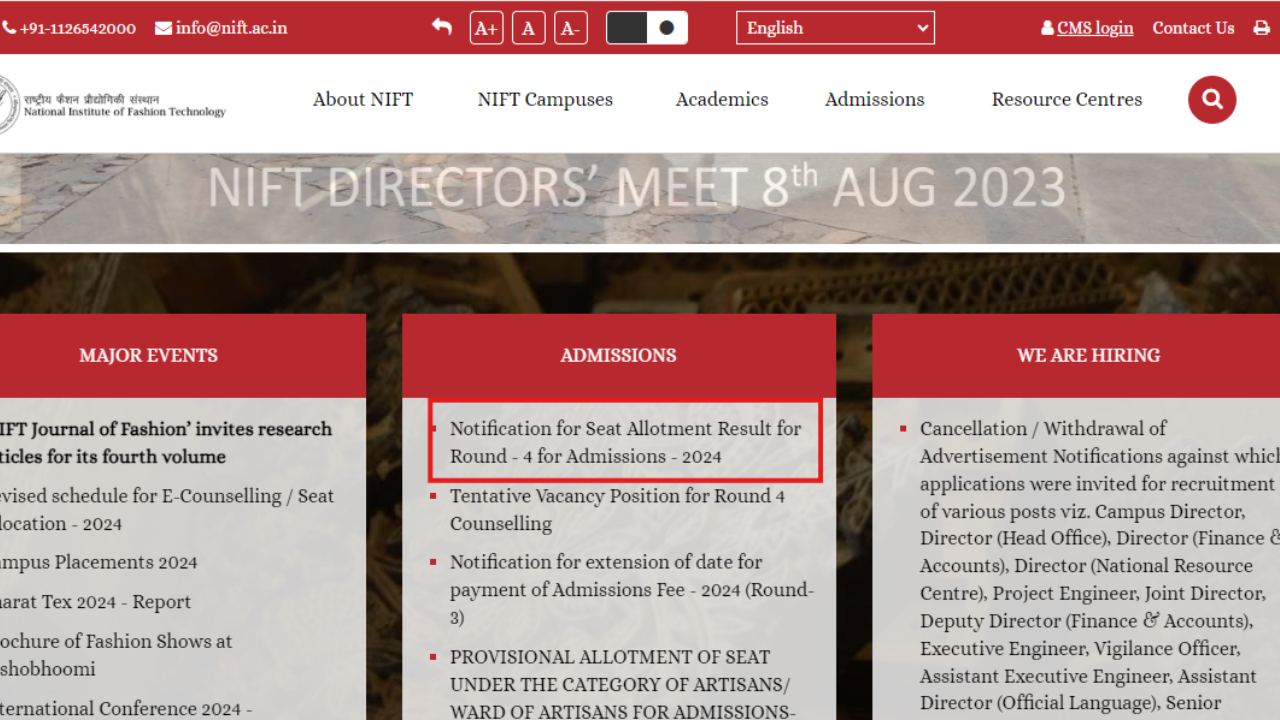

Copy link Copied Copy link Copied Subscribe to gift this article Gift 5 articles to anyone you choose each month when you subscribe. Already a subscriber? Login The warp machine’s mechanical march makes up just one part of the percussive symphony at Waverley Mills on the outskirts of Launceston. Two parallel bars rise and fall in constant motion, lifting alternating woollen warp threads while the weft threads shoot across in between.

The checked woven cloth appears centimetre by centimetre, slowly rolling onto a huge spool before being cut into blankets made from pure Tasmanian merino wool. The Terrain Throw from the Tasmanian Wilderness Collection in Tarkine Forest, made from 70 per cent virgin wool and 30 per cent recycled wool. Walking into Waverley Mills is like having one foot firmly planted in the past and one stepping boldly into the future.

At the end of one of its three buildings, you’ll spy a floor scale that once weighed bales of wool brought in by horse and cart from the surrounding farms. In another building, a new, state-of-the-art machinery winds thread onto bobbins, using robotic sensors for quality control, and cutting and rejoining threads of its own accord. “It’s a pretty special place,” says chief executive David Giles-Kaye, looking out of a huge window to the clear waters of Distillery Creek outside.

“I just thought this was a once-in-a-lifetime opportunity to be part of helping to bring something like this into the long-term future.” Waverl.