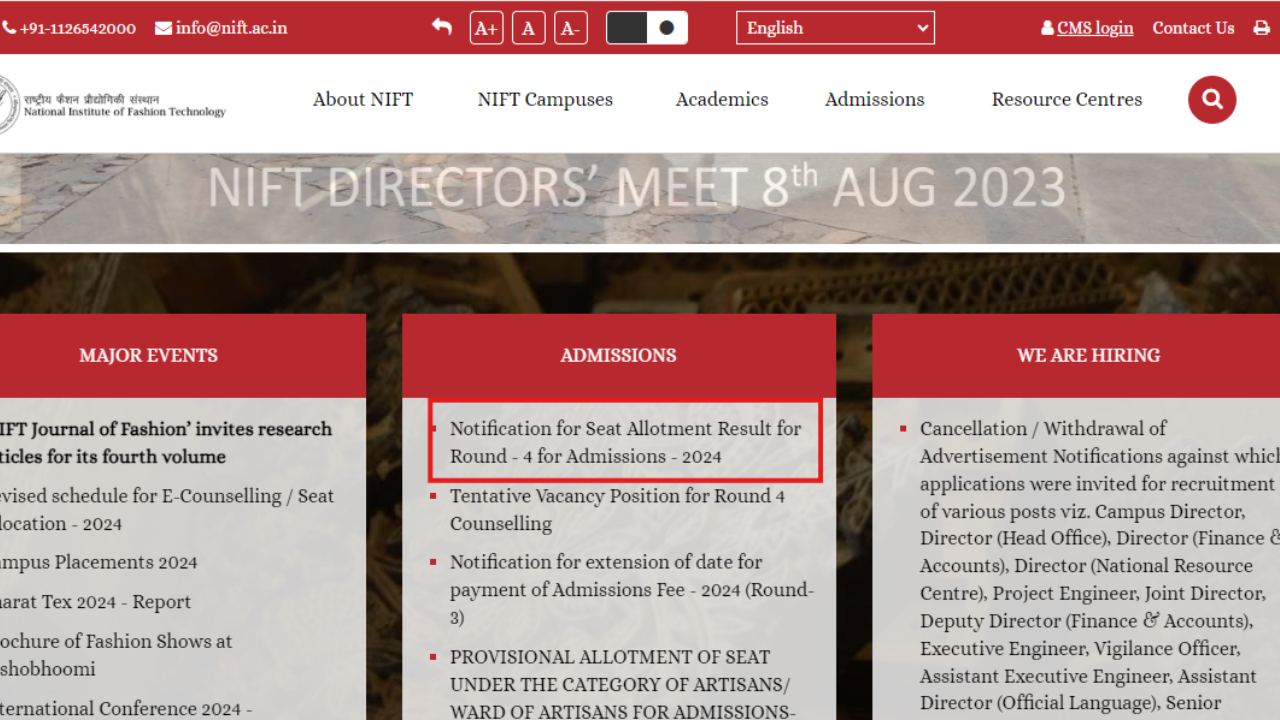

Fabric samples line the walls of the “materials library” in Baltimore-based Under Armour’s innovation labs in a corner of Building 37 on a corporate campus in Baltimore Peninsula. A trend board for spring 2026 stands nearby, meant to inspire with its display of athletic shoe uppers in the latest textiles. The textiles team meets here with product designers to select fabrics for seasonal apparel pieces and hash out fabric ideas.

Team members aim to find the best intersection of sportswear and innovation, in areas such as performance and durability, for the market. “Our textiles have to perform,” said Kyle Blakely, Under Armour’s senior vice president of innovation, development and testing. “We have an expectation from the consumer that we’re a performance brand.

...

That’s what makes our brand so different. ..

. When you buy our fabrics, you don’t have to sacrifice performance or sacrifice comfort. You get both.

” In textiles, product design, testing and manufacturing, Under Armour is doubling down on technical innovation. Officials believe it will remind consumers of the sportswear maker’s roots, propel a turnaround for the faltering brand and push it ahead of a growing pack of competitors. The reemphasis on innovation comes at a critical time for a company that invented a sweat-wicking T-shirt nearly three decades ago and rapidly grew into a multibillion-dollar sports apparel and footwear maker.

But in recent years, sales, profits and the company’s st.