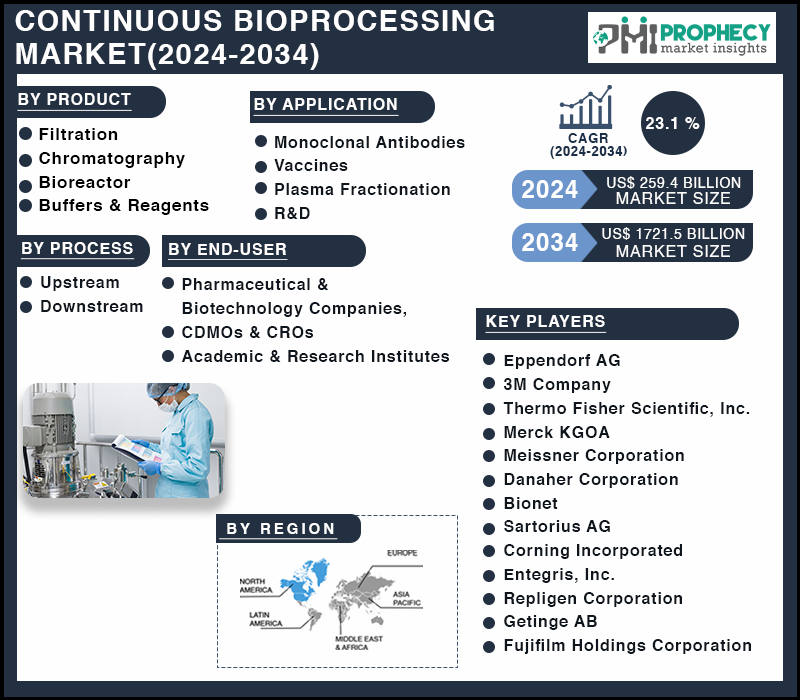

Covina, June 27, 2024 (GLOBE NEWSWIRE) -- In biomanufacturing, continuous bioprocessing is used to mean a processing unit wherein the feeding of raw materials, processing, and discharge happens as a continuum. Continuous process in a bioreactor operation mode: that will extend the production phase of a culture growing at a steady state—at a constant pace and constant circumstances—to give higher yields of biomass and metabolites. Some benefits of continuous manufacturing include increased product uniformity and quality, greater output in less square footage, fewer hold steps, and higher production speed using plug-and-play equipment.

While traditional batch processing runs on stop-start cycles, continuous bioprocessing integrates all its production stages from cell growth to purification in a single continuous flow. Picture a biofactory working like an assembly line where raw materials are fed in at one end and finished drugs come out from the other without any stoppages. The new approach has advantages such as reduced risk of contamination from the batch processes, better consistency in the quality of the product, and far greater productivity since there is reduced downtime in between the batches.

Besides, continuous bioprocessing takes less space in a facility with fewer footprints and hence can turn out to be more flexible to changes in production. The market for continuous bioprocessing is propelled by the growing need for biopharmaceuticals, pharmaceutical companies'.